WEST LAFAYETTE, Indiana, May 11, 2020 (ENS) – Mining for rare earth metals is about to become more environmentally and economically feasible though a process newly developed and patented at Purdue University.

These new environmentally-friendly technologies promise to be game-changers in this field and could enable the United States to create a more stable and reliable domestic source of these essential metals.

Used in computers, cell phones, DVDs, rechargeable batteries, catalytic converters, magnets, wind turbines, and fluorescent lights, and for defense in laser range-finders, guidance systems, and precision-guided weapons, these metals are difficult to mine because it is unusual to find them in concentrations high enough for economical extraction.

In addition, the detrimental environmental impact of current acid-based separation and purification of rare earth metals prohibits most companies everywhere in the world from entering the market.

China is currently the world leader in rare earth production, although it controls just 36 percent of the world’s reserves of these 17 metals. This provides an opportunity for other countries to become producers now that China is not selling rare earth materials below the cost of production as it did in the 1980s and ’90s.

But when China reduced the export quotas for rare earth metals in 2010, the costs of rare earth magnets for one wind turbine soared from $80,000 to $500,000. After China relaxed the export restrictions 18 months later, prices returned to lower levels than in 2010.

China is also the dominant consumer of rare earth metals for manufacturing electronics products for domestic and export markets. Today Japan and the United States are the second and third largest consumers of rare earth materials.

“About 60 percent of rare earth metals are used in magnets that are needed in almost everyone’s daily lives. These metals are used in electronics, airplanes, hybrid cars and even windmills,” said Nien-Hwa Linda Wang, the Purdue professor of chemistry who developed the new processes.

“We currently have one dominant foreign source for these metals and if the supply were to be limited for any reason, it would be devastating to people’s lives,” Wang said. “It’s not that the resource isn’t available in the U.S., but that we need a better, cleaner way to process these rare earth metals.”

Now the United States is moving to reclaim its top-flight rare earth metals mining and production status, and Purdue’s new processes are playing a big role.

The new patented extraction and purifying processes use ligand-assisted chromatography, a separation method that has been shown to remove and purify rare earth metals from coal ash, recycled magnets, and raw ore safely, efficiently and with virtually no detrimental environmental impact.

The production of rare earth metals is a global US$4 billion annual market that continues to grow as new electronics, computerized engines for aircraft, warships, electric automobiles, magnets, and other critical products are developed that require rare earth metals to perform. The value of the products using rare earth metals to function is valued at more than $4 trillion per year.

Hasler Ventures, a Florida company founded in partnership with Purdue University and the Purdue Foundry, has secured first rights to commercialize the technology’s intellectual property from the Purdue Research Foundation.

“It’s a supply chain challenge with wide implications on the U.S. economy and national security,” said Dan Hasler, founder of Hasler Ventures.

“We have a critically needed product and one dominant source for this product. This new patented process promises to enable U.S. independence from the China near monopoly,” Hasler said.

“This technology has been researched and developed at Purdue University for more than a decade and has proven to be versatile and robust,” he said.

“Conventional methods for producing high-purity rare earth elements employ two-phase liquid–liquid extraction methods, which require thousands of mixer-settler units in series or in parallel and generate large amounts of toxic waste,” Wang said.

“We use a two-zone ligand-assisted displacement chromatography system with a new zone-splitting method that is producing high-purity (>99%) metals with high yields (>99%).”

Wang’s ligand assisted method has the potential for efficient and environmentally friendly purification of the rare earth metals from all sources of recyclates, such as waste magnets and ore-based sources and helps transform rare earth processing to a circular, sustainable process.

“We continue to work diligently in the lab to learn how to adapt the ligand-assisted system to many variations we see in source material and are excited to collaborate with and assess the suitability of potential partners’ source material – be it recycled magnets and batteries, coal ash or domestically mined ore, Wang said.

Joe Pekny, a Purdue professor of chemical engineering, said Wang’s innovation enables the United States to reenter the rare earth metals market in an earth-friendly, safe and sustainable way. “What’s exciting is that the U.S. has the rare earth metals to meet the growing demands of the U.S. market and other markets around the globe and reduces our dependence on foreign sources,” Pekny said.

This research was funded in part by the U.S. Department of Defense, DoD.

Now, the Defense Department is supporting the U.S. rare earth supply chain with a new contract to a once defunct uranium mine in the California desert that is now the only rare earth mining and processing site in North America.

On April 22, MP Materials, owner and operator of the Mountain Pass Rare Earth Mining and Processing facility, was chosen by the Defense Department for a contract aimed at restoring domestic rare earth production to the United States.

With over 200 employees, MP Materials produces roughly 15 percent of global rare earth metal content.

“We appreciate the DoD’s leadership in addressing U.S. supply chain vulnerabilities. That is MP’s core mission, and we look forward to continued partnership with DoD in tackling this critical challenge,” said MP Materials Co-Chairman James Litinsky.

“We are committed to restoring the full rare earth supply chain to the United States,” Litinsky said, “paving the way for the onshoring of robust and diverse industries that will thrive through global competition, world-class products, and sustainable environmental standards.”

While MP Materials does not use the new Purdue process, the company does comply with federal and California environmental standards and uses a closed-loop zero discharge process.

“The dry-stacked tailings process allows our milling beneficiation process to consumer 1/20th of the freshwater of a comparably-sized facility, while our on-site Chlor-Alkali facility recycles our waste brine water from the separations facility and converts it into the chemical reagents needed for the separation process via electrolysis powered clean natural gas,” the company says on its website.

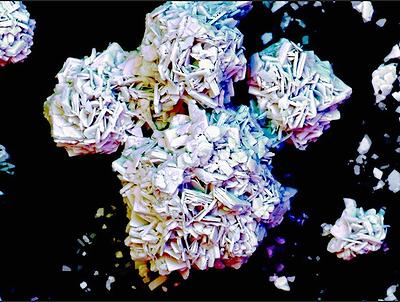

What are the rare earth minerals? According to the U.S. Geological Survey, “The rare earths are a relatively abundant group of 17 elements composed of scandium, yttrium, and the lanthanides. The elements range in crustal abundance from cerium, the 25th most abundant element of the 78 common elements in the Earth’s crust at 60 parts per million, to thulium and lutetium, the least abundant rare-earth elements at about 0.5 part per million.”

Copyright Environment News Service (ENS) 2020. All rights reserved.

© 2020, Environment News Service. All rights reserved. Content may be quoted only with proper attribution and a direct link to the original article. Full reproduction is prohibited.