AUSTIN, Texas, April 28, 2022 (ENS) – An enzyme variant created by engineers and scientists at the University of Texas at Austin can break down environment-strangling plastics that typically take centuries to degrade in a matter of hours to days.

The enzyme has the potential to supercharge recycling on a large scale that would allow major industries to reduce their environmental impact by recovering and reusing plastics at the molecular level.

This discovery, published Wednesday in the journal “Nature,” could help solve one of the world’s most pressing environmental problems – what to do with the billions of tons of plastic waste piling up in landfills and polluting lands and water.

“The possibilities are endless across industries to leverage this leading-edge recycling process,” said Hal Alper, an award-winning professor of chemical engineering at the University of Texas, Austin.

“Beyond the obvious waste management industry, this also provides corporations from every sector the opportunity to take a lead in recycling their products. Through these more sustainable enzyme approaches, we can begin to envision a true circular plastics economy,” Alper said.

The project focuses on polyethylene terephthalate, or PET, a polymer found in consumer packaging, such as cookie containers, soda bottles, fruit and salad packaging, and certain fibers and textiles. It makes up 12 percent of all global waste.

The enzyme was able to complete a “circular process” of breaking down the plastic into smaller parts, a process known as depolymerization, and then chemically putting it back together, repolymerization. In some cases, these plastics can be fully broken down to monomers in as little as 24 hours.

Researchers at the UT Austin Cockrell School of Engineering and College of Natural Sciences used a machine learning model to generate novel mutations to a natural enzyme called PETase that allows bacteria to degrade PET plastics.

“This work really demonstrates the power of bringing together different disciplines, from synthetic biology to chemical engineering to artificial intelligence,” said Andrew Ellington, professor in the Center for Systems and Synthetic Biology whose team led the development of the machine learning model.

The model predicts which mutations in these enzymes would accomplish the goal of quickly depolymerizing post-consumer waste plastic at low temperatures.

The research involved studying 51 different post-consumer plastic containers, five different polyester fibers and fabrics and water bottles all made from PET.

Through this process the researchers proved the effectiveness of the enzyme, which they are calling FAST-PETase, short for functional, active, stable and tolerant PETase.

In their study, the scientists explain, “We demonstrate that untreated, postconsumer-PET from 51 different thermoformed products can all be almost completely degraded by FAST-PETase in 1 week. FAST-PETase can also depolymerize untreated, amorphous portions of a commercial water bottle and an entire thermally pretreated water bottle at 50 ºC.”

“Finally,” the scientists write, “we demonstrate a closed-loop PET recycling process by using FAST-PETase and resynthesizing PET from the recovered monomers. Collectively, our results demonstrate a viable route for enzymatic plastic recycling at the industrial scale.”

Recycling is the most obvious way to cut down on plastic waste. But globally, less than 10 percent of all plastic has been recycled.

The most common method for disposing of plastic, besides throwing it in a landfill, is to burn it, which is costly, energy intensive, and spews noxious gases into the air. Alternative industrial processes are also very energy-intensive.

Biological solutions take much less energy. Research on enzymes for plastic recycling has advanced during the past 15 years. However, until now, no one had been able to figure out how to make enzymes that could operate efficiently at low temperatures to make them both portable and affordable at large industrial scale.

FAST-PETase can perform the process at less than 50 degrees Celsius, 122 degrees Fahrenheit.

Next, the team plans to work on scaling up enzyme production to prepare for industrial and environmental application.

The researchers have filed a patent application for the technology and are looking at several different uses. Cleaning up landfills and greening high waste-producing industries are the most obvious. But another key potential use is environmental remediation. The team is looking at a number of ways to get the enzymes out into the field to clean up polluted sites.

“When considering environmental cleanup applications, you need an enzyme that can work in the environment at ambient temperature. This requirement is where our tech has a huge advantage in the future,” Alper said.

Alper, Ellington, associate professor of chemical engineering Nathaniel Lynd, and Hongyuan Lu, a postdoctoral researcher in Alper’s lab, led the research.

The work was funded by ExxonMobil’s research and engineering division as part of an ongoing research agreement with UT Austin.

See the full research study, “Machine learning-aided engineering of hydrolases for PET depolymerization,” here. https://www.nature.com/articles/s41586-022-04599-z

To see a time-lapse video of the depolymerization process, click here. https://www.eurekalert.org/multimedia/932058

With plastic collecting everywhere on Earth from mountain to beach to landfill, there’s an urgent need to cut the amount of discarded plastics. Chemists around the globe are working to make it easier to recycle and turn into higher-quality useful materials.

“There’s not going to be a single technology that’s going to be the answer,” says Ed Daniels, senior project manager at the REMADE Institute in West Henrietta, New York, which funds research into new recycling techniques.

Some projects are on the brink of breaking into industry; others are still just promising lab experiments, said Daniels, who was not involved in the UT Austin research. All projects are focused on designing a future where any plastic that ends up in the recycling bin can have a second and third life in a new product.

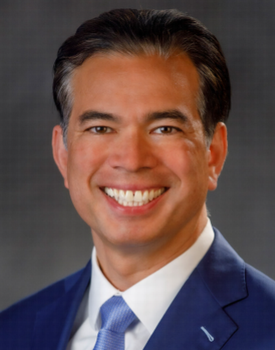

But it is exactly that kind of assertion that California Attorney General Rob Bonta has decided to investigate.

Today, Bonta announced an investigation into the fossil fuel and petrochemical industries for their role in causing and exacerbating the global plastics pollution crisis. “For decades,” he says, “these industries have aggressively promoted the development of oil-based plastic products and campaigned to minimize the public’s understanding of the harmful consequences of these products.”

Attorney General Bonta’s investigation will examine the industries’ historic and ongoing efforts to deceive the public and whether, and to what extent, these actions may have violated the law.

As part of the investigation, the Attorney General today issued a subpoena to ExxonMobil, a major source of global plastics pollution, seeking information relating to the company’s role in deceiving the public.

“In California and across the globe, we are seeing the catastrophic results of the fossil fuel industry’s decades-long campaign of deception. Plastic pollution is seeping into our waterways, poisoning our environment, and blighting our landscapes,” said Bonta. “Enough is enough.”

“For more than half a century, the plastics industry has engaged in an aggressive campaign to deceive the public, perpetuating a myth that recycling can solve the plastics crisis. The truth is: the vast majority of plastic cannot be recycled, and the recycling rate has never surpassed nine percent,” Bonta asserted.

“Every week, we consume the equivalent of a credit card’s worth of plastic through the water we drink, the food we eat, and the air we breathe,” he said. “This first-of-its-kind investigation will examine the fossil fuel industry’s role in creating and exacerbating the plastics pollution crisis – and what laws, if any, have been broken in the process.”

Featured image: Mountain of plastic waste. Undated (Photo courtesy Royal Society of Chemistry)